Multi station automatic cold heading machine

Source:http://www.politicsinalabama.com Author:冷鐓機 Time:2014/8/16 Click:

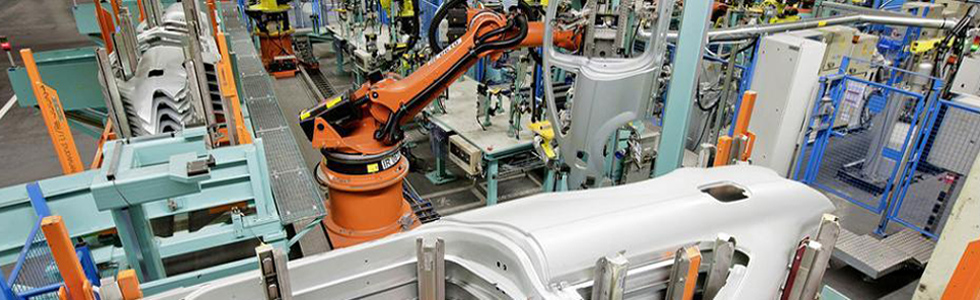

Overview of Multi station Automatic Cold Heading Machine

The multi station automatic cold heading machine uses cold heading method to automatically punch various hexagonal nuts from optical disc elements or bar materials, and then thread them to produce standard hexagonal nuts

The bar material is fed through roller drive, and is sequentially fed, cut, pressed, angled, punched, and several processes are completed in one machine The cold heading station is arranged horizontally and has the characteristics of accurate positioning, stable operation, and convenient maintenance, making it suitable for manufacturers to mass produce nuts Multi station automatic cold heading machine is a specialized equipment for producing hexagonal nuts and some non-standard components. Using single-sided S-board cutting is more stable and powerful, and the time can be adjusted.

Characteristics of multi station automatic cold heading machine

1. Horizontal arrangement of forging stations

2. Use a clamp to transport workpieces, and the opening and closing time of each clamp can be adjusted separately

3. Use a round socket cutter with a smooth cut

4. The transmission of the main action mechanisms (cutting, die ejection, feeding, etc.) adopts a connecting rod form

5. Meet the requirements of large plate round feeding

6. Equipped with a wire rolling mechanism, it realizes automated production of bolts and screws from cutting, forging to wire rolling in one line

7. The concave die of the third station is suitable for edge cutting or forging processes, and easy to change and adjust

8. Each workstation has a punch ejection mechanism that can be adjusted separately

9. The clutch and brake with pneumatic control enable the main motor to start under no load, with flexible movement and convenient debugging of the machine tool. When stopping, the main slider automatically stops at the rear dead center

Precautions for using multi station automatic cold heading machine

(1) The diameter of steel bars or wires should meet the requirements of a multi station cold heading machine, and steel bars (wires) that are too coarse or too fine cannot be cold headed;

(2) Within the allowable range of the cold heading diameter of the cold heading machine, the position of the fixture (screw in or screw out) can be adjusted according to the required anchor head size to obtain a suitable amount of steel bar (wire) extension allowance;

(3) Within the 120-130mm area of the cold heading part of the steel bar (wire), rust removal and straightening are required;

(4) The end of the steel bar should be ground flat to ensure the accurate shape of the cold heading anchor head;

(5) After the steel bar is upset, it must undergo a tensile test to verify whether the strength of the anchoring head is qualified.

- 上一篇:Nut Cold Heading Machine _ Nut 2014/8/17

- 下一篇:Cold heading technology of col 2014/8/16